Turbo Component or Assembly Balancing

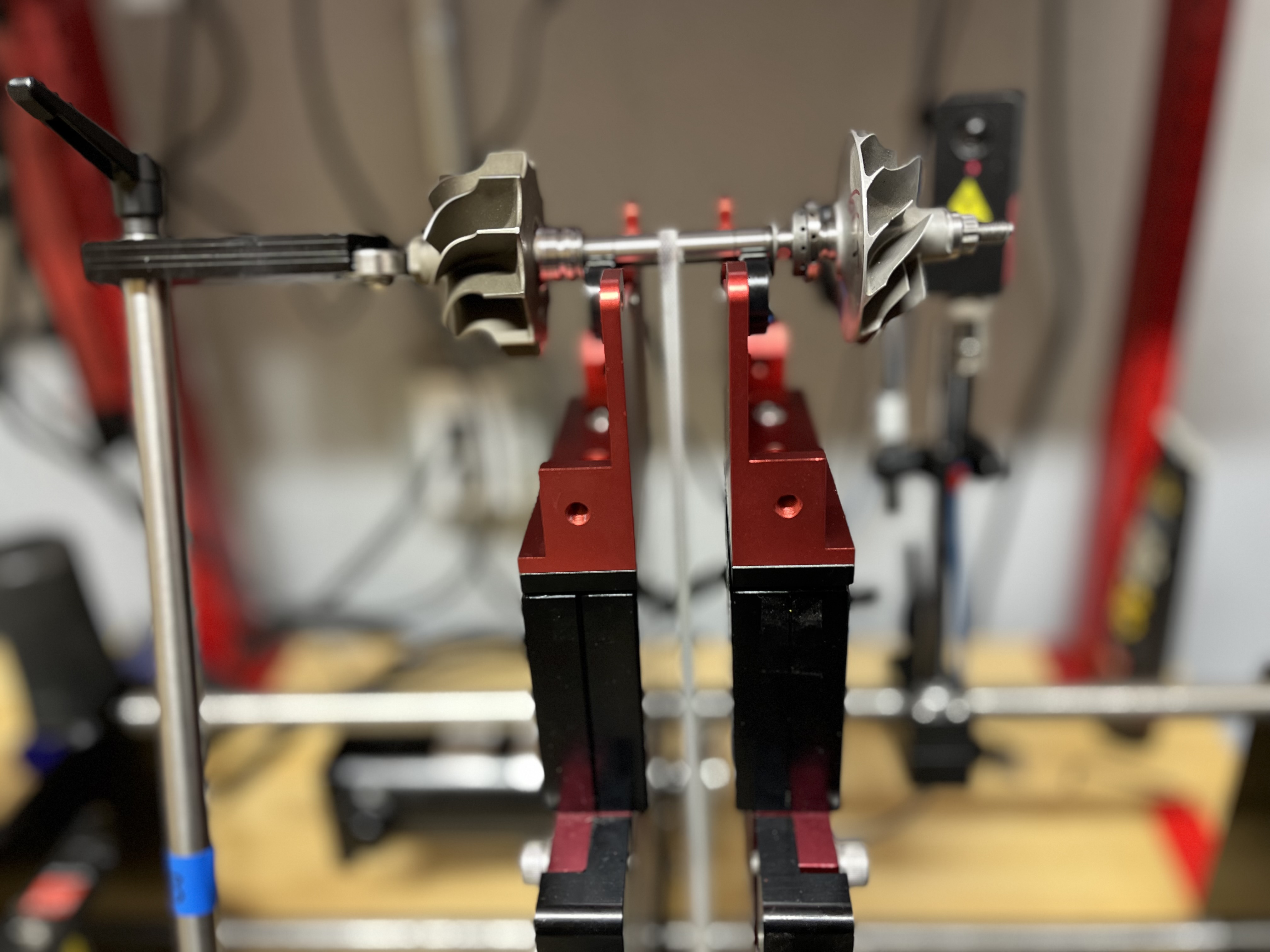

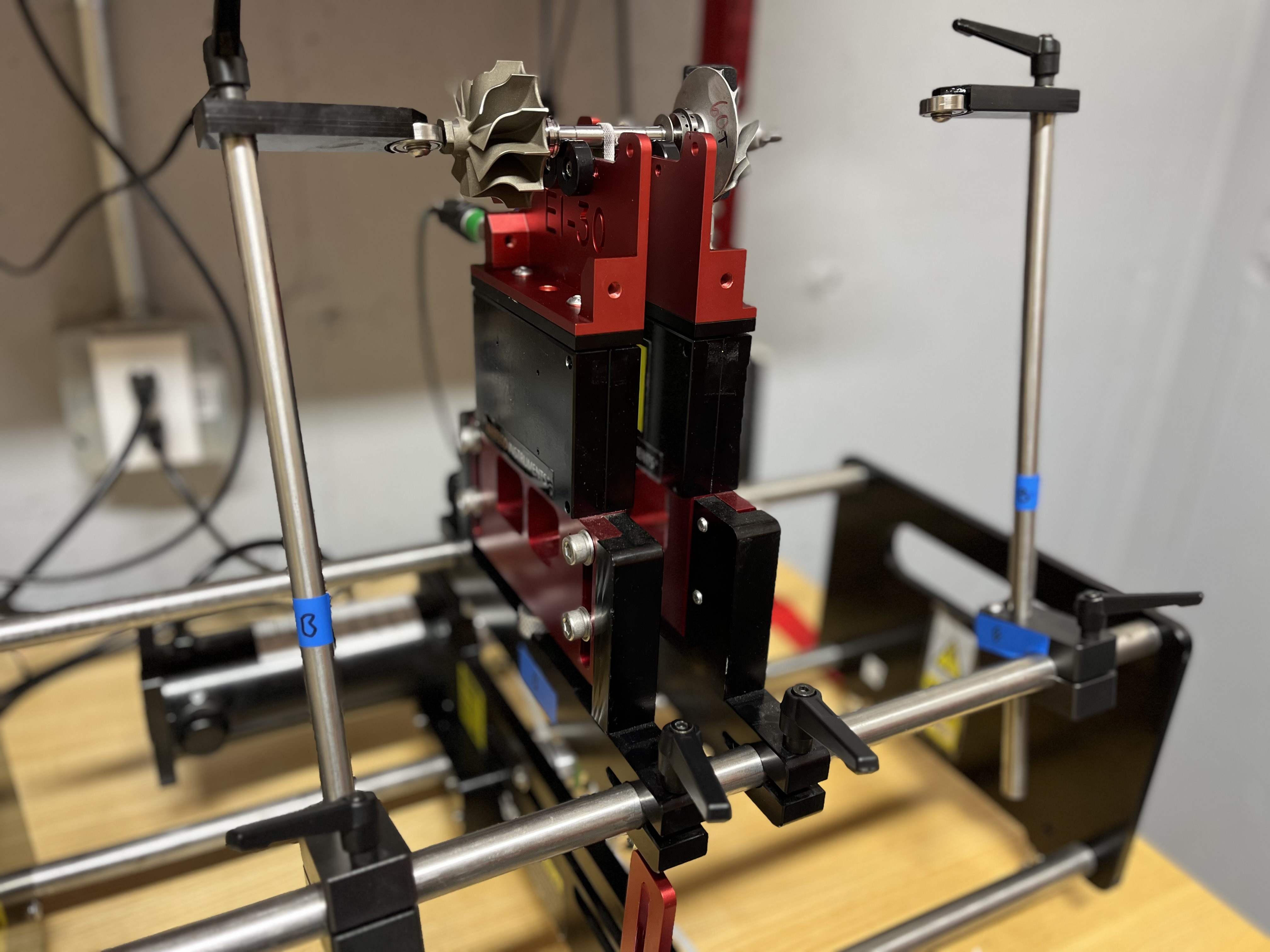

Did you rebuild your turbo yourself, awesome we applaud you for being a DIY-er, or maybe your wanting to install a different turbine or compressor wheel, we have you covered. We have two balancing machines, both made from one of the leaders when it comes to Balancing Technology named CIMAT and Erbessed. Our equipment is well maintained and checked periodically to ensure they are still balancing to ANSI ISO 21940-21:2022 specifications for Mechanical Vibration Rotor Balancing.

We offer three types of balancing low speed rotor group balancing (Compressor Wheel, Turbine wheel and Shaft, Thrust Collar & Compressor nut). Low Speed CHRA (Center Housing Rotating Balancing) Cartridge Balancing and High Speed VSR (Vibration Sorting Rig) core or CHRA balancing. Since balancing is such a precise process, all Turbine Wheel and Shafts are checked for shaft straightness.

Why Balancing Is Required?

Turbochargers are like a wheel and tire on a car, while both are balanced from the factory, once put together as an assembly they require additional balancing due to imbalances and frequences they create once together. Every time a component is replaced or the rotor group loses index, balancing should be performed. Turbochargers are very precise and are balanced down to 0.05grams of imbalance in certain applications and when not in proper balance, those forces can push through the fluid film barrier seperating allowing for contact between major components to happen. Since modern turbos operate at speeds upwards of 150,000 rpms, this slight contact can catastrophically destroy a turbo in seconds.

Two Plane Dyanmic Balancing (Low Speed): This is where the majority of material is removed as an imbalance at any speed, carries the same level of imbalance. So 10grams of imbalance at 100RPM's is still 10grams of imbalance at 300,000RPM's.

High Speed VSR Balancing: This is where fine tuning comes into play for turbos that exceed 80,000RPM's as they generally require VSR balancing. VSR balancing plays to major roles, which is cut down on NVH (Noise Vibration and Harshness) and then shows any additional imbalances throughout various RPM ranges. Rotor groups while solid, produce flex and that flex at various RPM's is where you will see the imbalances and NVH. Think back to the Wheel and Tire example, you may not have a vibration at 65mph, but at 70mph you have a vibration. VSR balancing measures this throughout the entire operating range and you remove small amounts of material of the rotor group to clear up those unwanted frequencies and harmonics.

Balancing Cost:

Hourly Rate: $65 per/hr

Low Two Plane Speed Balancing: 1.5hrs avg. ($97.50 avg.)

Low Speed CHRA Balancing: 1.5hrs avg. ($97.50 avg.)

High Speed VSR Balancing: 2hrs avg. ($130.00 avg.)

Low Speed Two Plane Dynamic Balacing: (2,000-6,000rpms)

Working Rotor Group Diameter Max: 200mm

Components Required: Turbine Wheel & Shaft, Compressor Wheel, Thrust Collar and Compressor Wheel Nut

Process:

- Items are cleaned if required

- Turbine Wheel and Shaft are checked for straighness. If the shaft is bent, we will reach out to speak about next steps

- Rotor Group is assembled and torqued to spec

- Rotor Group is measured to get accurate balancing required specifications

- Indexing Lines are painted on one blade of each wheel

- Intial Run to check balance

- First cuts to both planes, compressor back face and turbine stage back face.

- Repeat previous two steps to get required balance, down to potentially 0.05gmm (Gram-Millimeter)

Once proper balance is acheived, we will place marks on the rotor group so that when you disassemble it, you can torque it back into the correct spot. We will also provide a balancing report for you for your safe keepking.

Low Speed Cartridge / CHRA (Center Housing Rotating Assembly): (4,000-40,000 RPM)

Working Rotor Group Diameter Max: 200mm

Components Required: Complete CHRA (Minus Turbine and Compressor Housing) Turbine Wheel & Shaft, Compressor Wheel, Thrust Collar, Thrust Bearing, Center Housing, Bearings, Heat Shield, Backplate and others depending on unit.

Process:

- Items are cleaned if required

- Turbine Wheel and Shaft is checked for straighness. If the shaft is bent, we will reach out to speak about next steps

- Rotor Group is assembled and torqued to spec

- Rotor Group is measured to get accurate balancing required specifications

- Indexing Lines are painted on one blade of each wheel

- Intial Run to check balance

- First cuts to both planes, compressor nose / wheel nut and turbine stage hub

- Repeat previous two steps to get required balance, down to potentially 0.05gmm (Gram-Millimeter) KG of Mass

Once proper balance is acheived, the rotating assmbly is ready to be installed in your housings. This process uses air to spin the rotor group and has oil running through it. It is ok if you see oil in the unit when returned, we try to plug the orfices but some will still leak out. A balance report will also be provided for this process.

High Speed VSR (Vibrational Sorting Rig) CHRA / Cartridge Balancing

Working Rotor Group Diameter Max: 179mm Compressor Wheel | 114mm Exducer / 134mm Inducer turbine wheels

Components Required: Complete CHRA (Minus Turbine and Compressor Housing) Turbine Wheel & Shaft, Compressor Wheel, Thrust Collar, Thrust Bearing, Center Housing, Bearings, Heat Shield, Backplate and others depending on unit.

Process:

- Items are cleaned if required

- Turbine Wheel and Shaft is checked for straighness. If the shaft is bent, we will reach out to speak about next steps

- Rotor Group is assembled and torqued to spec

- Rotor Group is measured to get accurate balancing required specifications

- Indexing Lines are painted on one blade of each wheel

- Intial Run to check balance

- First cuts to both planes, compressor nose / wheel nut and turbine stage hub

- Repeat previous two steps to get required balance, down to potentially 0.05gmm (Gram-Millimeter) KG of Mass

Once proper balance is acheived, the rotating assmbly is ready to be installed in your housings. This process uses air to spin the rotor group and has oil running through it. It is ok if you see oil in the unit when returned, we try to plug the orfices but some will still leak out. A balance report will also be provided for this process.

Want to your turbos components balanced, either fill the form out found below or reach out via the below contacts

Phone: 720-892-9546

Email: Customerservice@artturbos.com

Submission Form: Service Required Form